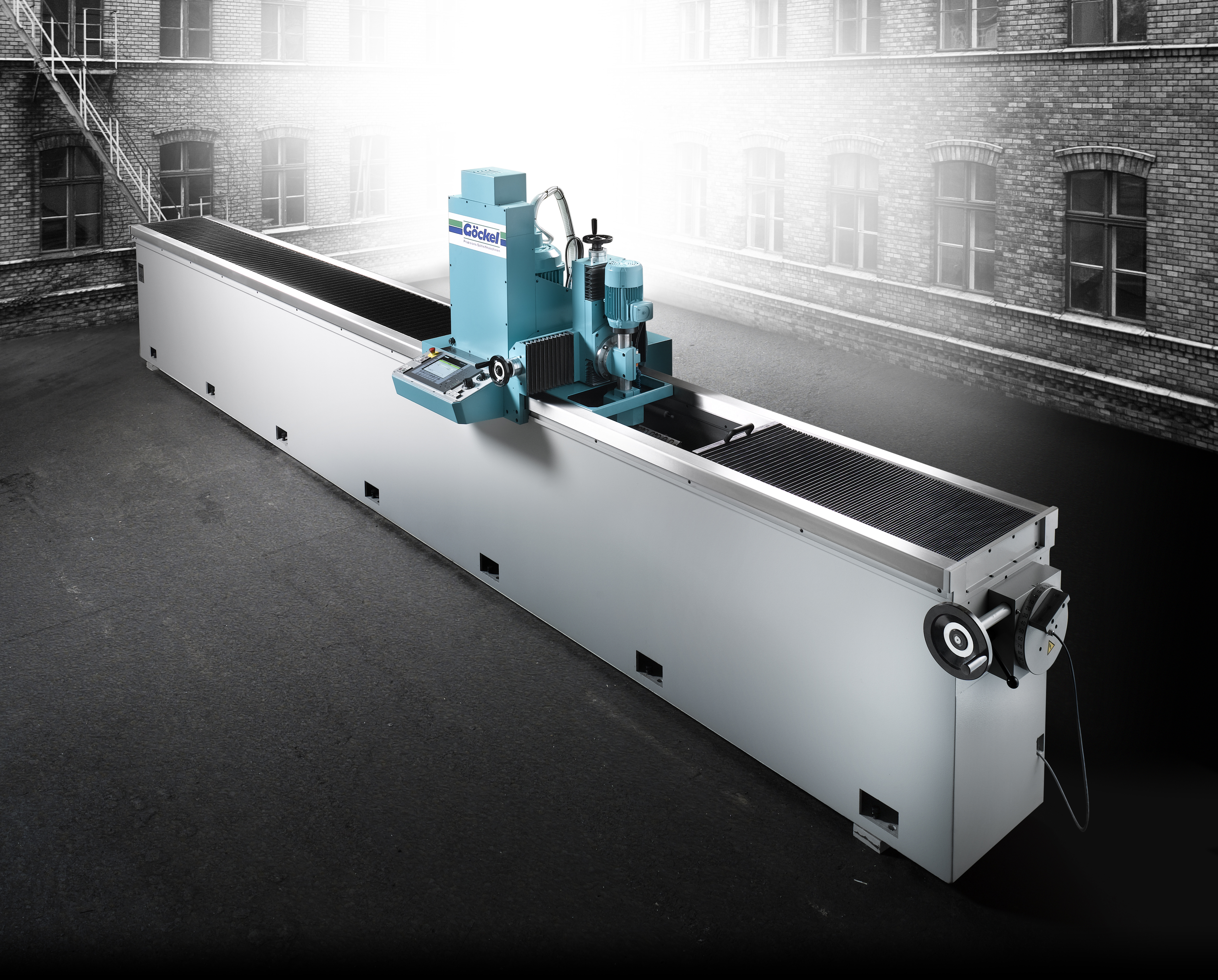

Straight Knife Grinders

Machine Construction

Machine Bed

Welded construction in cell design. Precision machined for the highest accuracy.

Guide Ways

Three systems available depending upon model and application:

- Hardened and ground way bands

- Bolted on hardened and ground box ways

- High precision linear ways covered with stainless steel guards

Machine Tables

- (PL) Flat fixed table

- (EL) Electromagnetic rotating table

- (ELD) Twin electromagnetic rotating tables

Grinding Carriage

Cast iron construction with precision guide rolls, support guiding and tapered gib.

Down Feed System

For grinding tool, ball screw and nut system. Impulse feed, rapid positioning, and digital display. Many options of programmability are available.

Grinding Motor

Strong hollow shaft for coolant supply and high precision bearings, tiltable for cross and radial grinding.

Grinding Tools

Ring type grinding wheel, segmental head, diamond or CBN grinding wheels. Diameter and size depend upon the model and application.

Traverse Drive

Variable brushless AC Servo or AC inverter drives

Coolant System

Large external coolant tank and pumps supply coolant through the hollow motor shaft and from the sides. Many filter options are available.

Electrical Cabinet

Separate installed cabinet using the latest technique in controls.

Accuracy

Grinding: +/- 0,005 mm/m

Options and Steps of Automation

- Magnetic quickchange device for grinding wheel

- Pendulum and creep feed grinding

- Electrical demag control for work-table

- NC and CNC controls

- Steplessly variable grinding motor

- Multiple chuck or two work station arrangements

- Automatic sizing unit with wheel wear compensation

- Grinding vapor extraction and enclosures

- Programable controls for automatic grinding cycles

- Special fixturing, handling systems and robotic automation